[ad_1]

When drivers of future Mercedes AMG fashions stomp the accelerator of their electrical efficiency automobiles, they’ll get further oomph out of the batteries from one thing that sounds straight out of “Again to the Future.”

No, not flux capacitors, however axial flux motors.

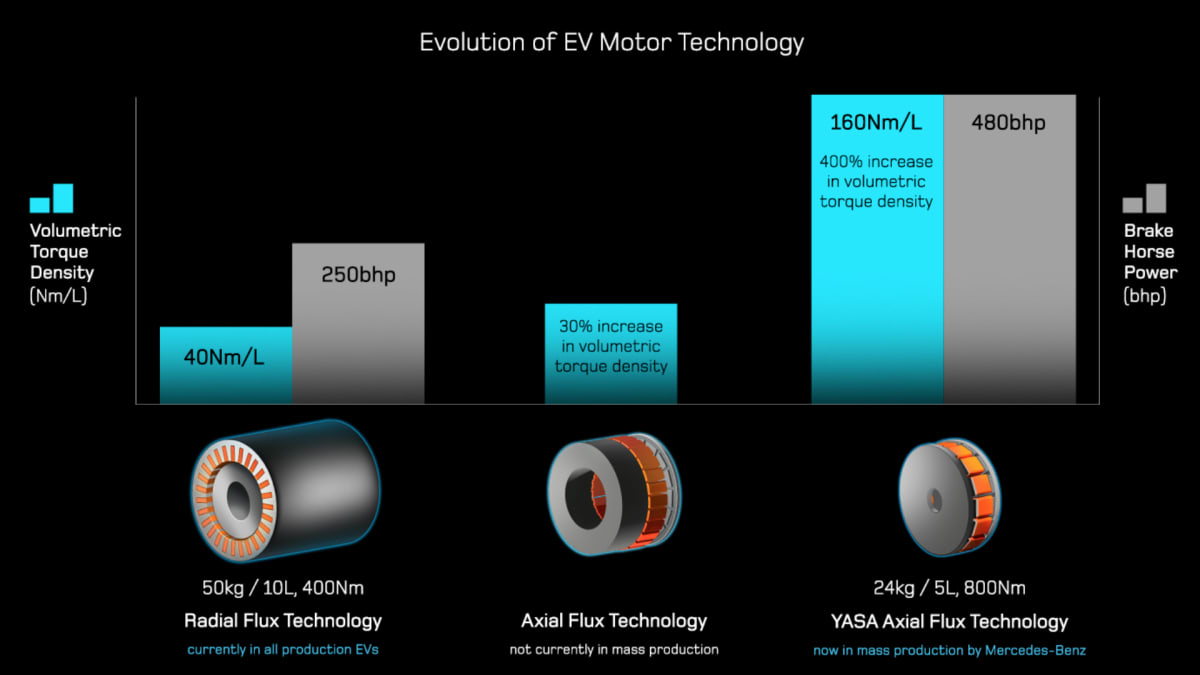

Mercedes-Benz AG and Ferrari NV are turning to this kind of electrical motor to generate headrest-hitting torque. Axial flux motors are a lot smaller than predominantly used radial motors, but pack a extra highly effective punch.

Excessive-end motors like these might be essential to manufacturers like AMG and Ferrari as they race to impress the high-performance automobiles that earn status and bumper earnings. All EVs supply the feeling of prompt acceleration, from Nissan’s Leaf to Tesla’s Model S Plaid. Whereas within the combustion age, faster instances off the road and better high speeds had been achieved with extra engine cylinders, producers will differentiate efficiency EVs by getting essentially the most out of batteries with lighter and extra environment friendly motors.

“The ability-to-weight ratio is known as a file quantity, and a lot better than standard motors,” Markus Schaefer, Mercedes’s chief know-how officer, stated of the automaker’s upcoming AMG electric vehicle platform. “It is going to make use of the small dimension of the motor.”

With every press of the accelerator, EV drivers push a whole lot — and in some circumstances hundreds — of amps of electrical present to copper coils. When these coils are energized, they turn into electromagnets with engaging and repulsive forces. The magnetic drive created by a stationary stator surrounding a rotating rotor produces the torque that turns the wheels of the car.

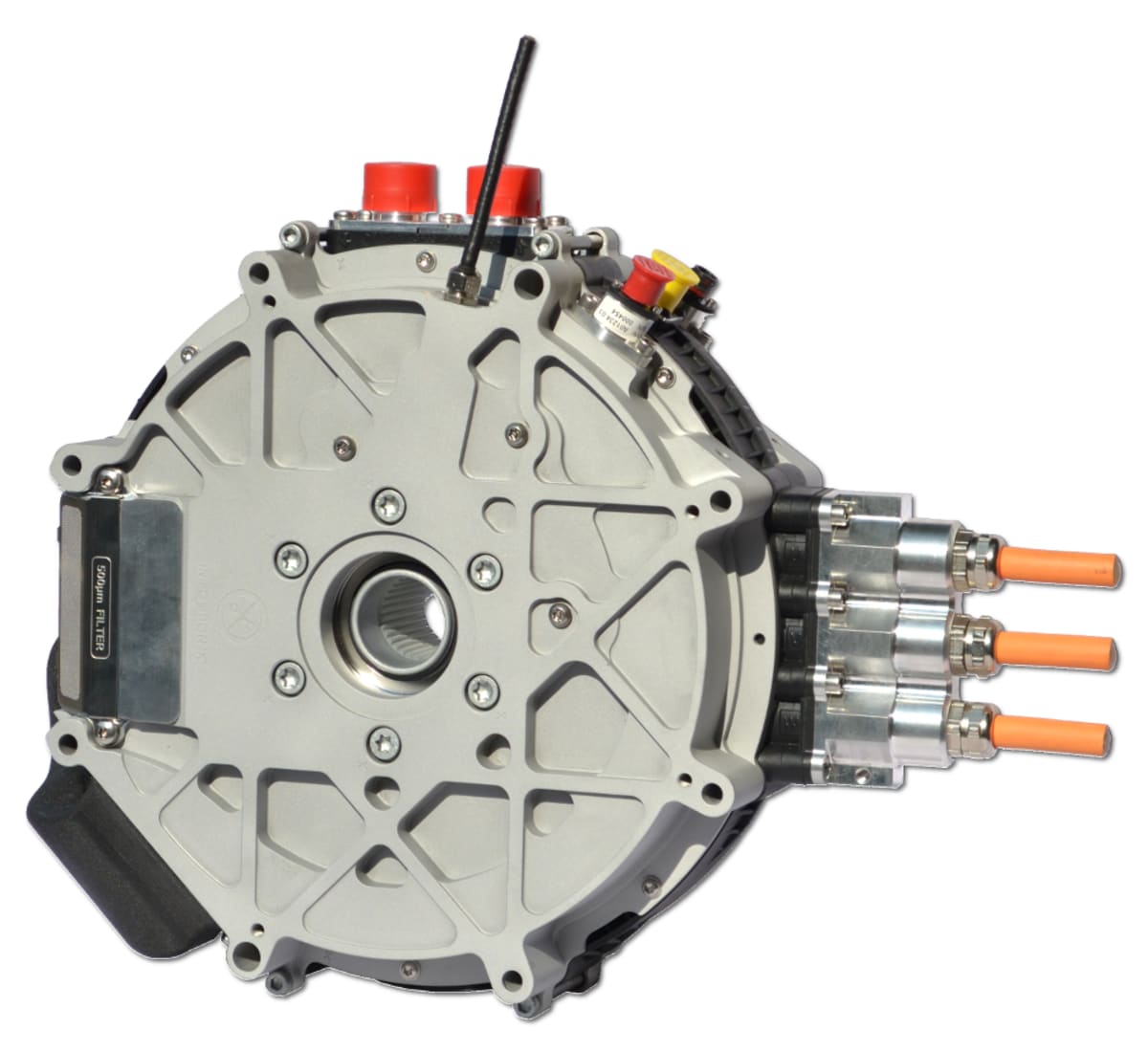

In axial motors, fairly than have a rotor spin inside a stator, disc-shaped rotors spin alongside a central stator. This leads the movement of present — the flux — to journey axially via the machine, fairly than radially out from the middle. Since the motor generates torque at a much bigger diameter, much less materials is required. Yasa, an Oxford, England-based producer of motors utilized in Ferrari’s SF90 and 296 GTB plug-in hybrids, makes use of just some kilograms of iron for its stators, decreasing the mass of the machines by as a lot as 85%.

Yasa’s motors are the brainchild of Tim Woolmer, whose work on them had been the main focus of his electrical engineering PhD on the College of Oxford. Inside a number of years of incomes his doctorate, Jaguar Land Rover made plans to make use of Yasa’s motors within the C-X75, a hybrid-electric two-seater with sufficient horsepower to rival the Porsche 918 Spyder, McLaren P1 and Ferrari LaFerrari. Whereas JLR ended up canceling the venture as a result of monetary constraints, Yasa’s motors discovered their approach into the Koenigsegg Regera hybrid hypercar, adopted by the Ferrari SF90.

In July of final 12 months, Mercedes introduced it had acquired Yasa for an undisclosed sum and would put its motors in AMG fashions slated to launch beginning in 2025.

“Should you take a look at the historical past of automotive usually, the auto corporations have wished to have the engine, their core know-how, in-house,” Woolmer stated in an interview. “The batteries, the motors, that is their core know-how now. They acknowledge the significance of getting long-term differentiation in these areas, in order that they must deliver it in-house.”

An important side of axial motors is form-factor potential, in keeping with Malte Jaensch, professor of sustainable cell drivetrains on the TUM College of Engineering and Design in Munich. Their smaller dimension may enable carmakers to place one motor on every wheel, which isn’t possible with radial motors.

Placing a motor on every wheel — or a minimum of one on every axle — may translate into hair-raising EV driving efficiency. The innovation permits for torque vectoring that higher controls how a lot energy the motors ship to every particular person wheel for improved agility. Excessive-speed cornering could assist AMG and Ferrari drivers recover from the misplaced roar of their eight-, 10- or 12-cylinder engines.

Yasa’s motors additionally may utterly take away the necessity for a powertrain on the so-called skateboard beneath the center of an EV, Woolmer stated. That may open up extra space for engineers to package deal batteries, make extra room for greater entrance and rear trunk areas, or enable designers to experiment with new aerodynamic concepts.

The small dimension and lightweight weight of axial motors gained’t simply profit high-performance automobiles. They’re additionally discovering a house in aerospace, main Yasa to spin out its electrical aviation division Evolito final 12 months. The world’s quickest electrical car, Rolls-Royce Plc’s electrical plane referred to as the Spirit of Innovation, makes use of three axial flux motors to drive its propeller. The plane can journey round 380 miles (612 kilometers) per hour, making it quicker than the Spitfire fighter plane that was powered by a Rolls-Royce V12 engine.

“The vital factor is their effectivity,” stated Matheu Parr, the Spirit of Innovation venture chief at Rolls-Royce. “This lets you hold the burden of the plane low.”

Axial motors gained’t essentially be the dying knell of radial motors, which ship greater high speeds. This led Ferrari to make use of two radial motors on the entrance axle of the SF90, together with an axial motor on the rear axle. For the 296 GTB, dealing with was deemed extra essential, so solely a lighter axial motor was used between the engine and transmission.

“It’s only a matter of what sort of driving expertise you wish to design on your prospects with a selected engine,” stated Davide Ferrara, Ferrari’s electrical motors supervisor. “Totally different voices make candy notes.”

Associated video:

Source link